Manufacturing Process

Centrifugal Casting

Ni-Hard Cast Iron

Precision Machining

CNC Turning

Precision Lapping

Spherical, Flat & Finish Lapping

Compression Rubber Molding

NBR,HNBR, NBR-LT, FKM, Silicon.

Precision Grinding

Centerless, Bore, Surface Grinding

Heat Treatment

Hardening Tempering- Cryogenic Treatment. Induction Hardening, Carburizing, Gas Nitrating, Laser Treatment, Plug Quenching

Surface Treatments

Shot Blasting, Amorphous Phosphating, CED Coating, MOS2 Coating, WS2 Coating, Zn Passivation.

Innovative Technologies

Innovation is the USP of SAP Parts. Moreover it is our core value and we intend to proactively employ innovative thinking culture in all our operations.

The Sealing Solutions Delivered by SAP Parts Involves a high end research and patented technology warranting the highest performance and application sustainability of Mechanical Face Seals at:

Max 10 M/s Surface Speed.

Most Severe Environmental Situations.

At SAP Parts, we continuously effort to pioneer developments that create competitive advantage with our parts. Our innovation plan and actions are in close collaboration with our suppliers, customers and human resources in order to meet the variable needs of customers, from time to time.

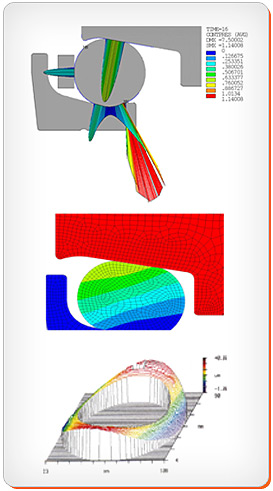

Ongoing Technological Developments (Due For Patent )

Max 10 M/s Surface Speed.

Model for Contact Surface Wear Life Prediction.

Elastomeric Variable Load Stress Relaxation Modeling.

Innovative Surface Treatments for Demanding Applications.

Innovative Surface Treatments for Demanding Applications.

Functional Conformance of Metallurgical Properties of Ni-Hard Cast Alloys & Sealing Surface Asperities in Abrasive Environment.